Product Innovation

Acme Energy

Building the future of the in-field technician experience

Acme Energy is one of the top oil and gas companies in the world – a “supermajor.” Acme wanted to explore ways to improve their technicians’ day-to-day, in-field workflows – primarily, by exploring ways create a digital experience for what has been, historically, completed using only a paper and pencil.

SUMMARY

ROLE

SENIOR DESIGNER

UX - VISUAL - RESEARCH

CONTRIBUTION

TIMELINE

5 MONTHS

PLATFORM

TABLET APP

DEFINE

Technicians are responsible for the maintenance and upkeep of oil and gas infrastructure, often, in some of the most extreme environments on the planet. Their existing workflow features a number of pain points, such as: switching between multiple applications and devices, printing documentation (like permits and technical diagrams), and missing or lost equipment.

The Challenge

Identify valuable use cases for mobile platforms that could improve overall workday efficiency. Use technology to compliment and support the needs of technicians both in office and in the field. Once aligned on a solution, design and build a functional MVP.

Our Goals

Acme Oil & Gas wanted to improve the technician experience, but wasn’t sure how. To uncover user needs and better align on opportunities, we held a series of discovery-focused research activities, including stakeholder interviews, desk research, remote user interviews, and in-person user interviews.

RESEARCH

FINDING 1

Device limitations, unstable interview and user experience challenges with existing devices and applications result in inconsistencies for information capture and task completion delays.

FINDING 2

Roadblocks created due to collaboration challenges and requirements of administrative tasks result in time-loss and delays.

FINDING 3

Poor planning has consequences leading to technicians carrying out additional steps to find the right materials, navigating extra activities that interrupt the planned day flow.

DELIVER

Our Solution

Create a single pane of glass (SPOG) application for use on industrial-grade tablets. The SPOG would create a single location for the technician to complete their maintenance tasks, a ‘digital work execution’ (DWE) app. Day-to-day maintenance responsibilities would be handled entirely through DWE – receiving assignments, material lists, permits, and tracking and recording functions.

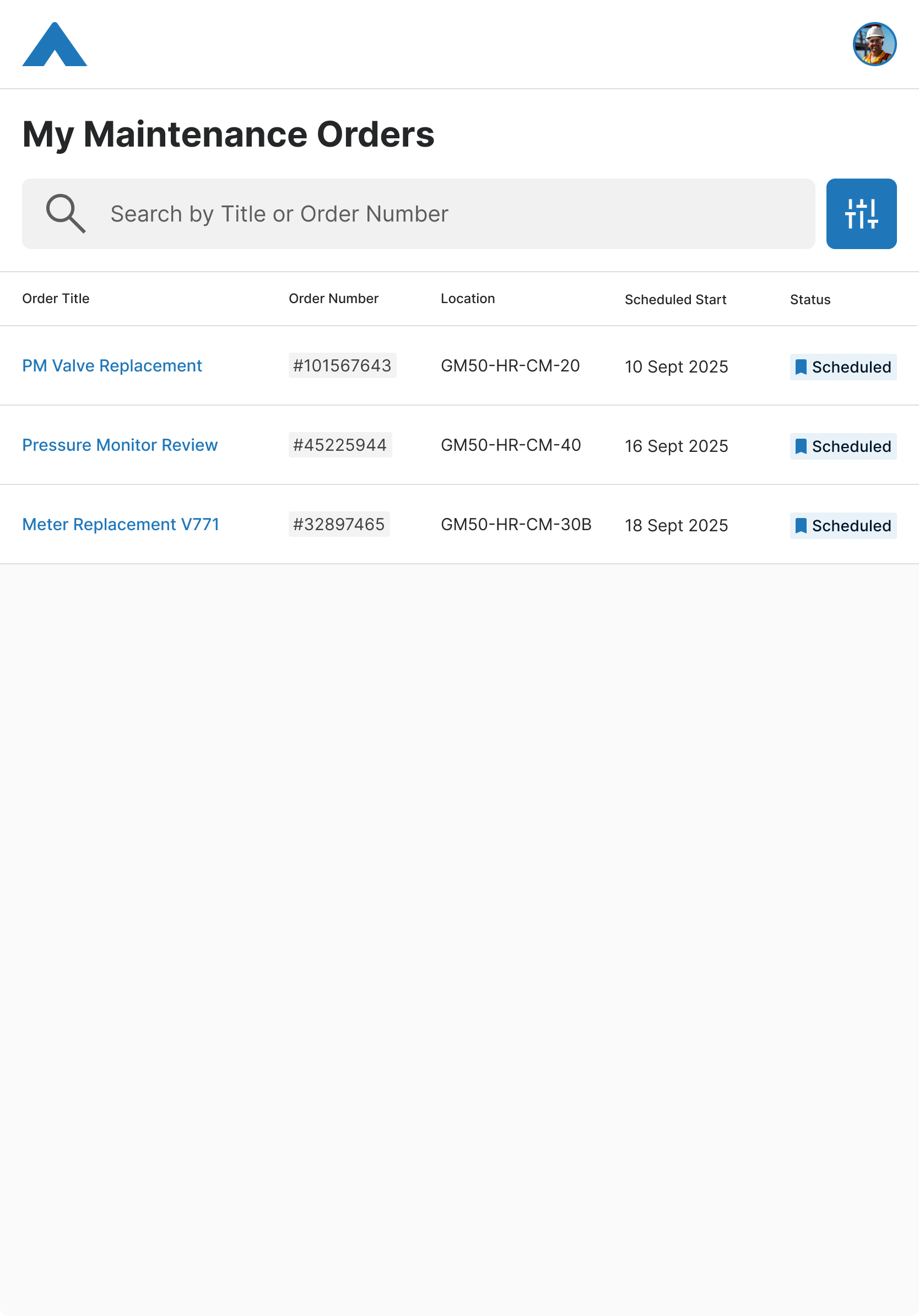

01 Digital Work Execution homepage - only projects assigned to the specific user will appear here

MAINTENANCE ORDER

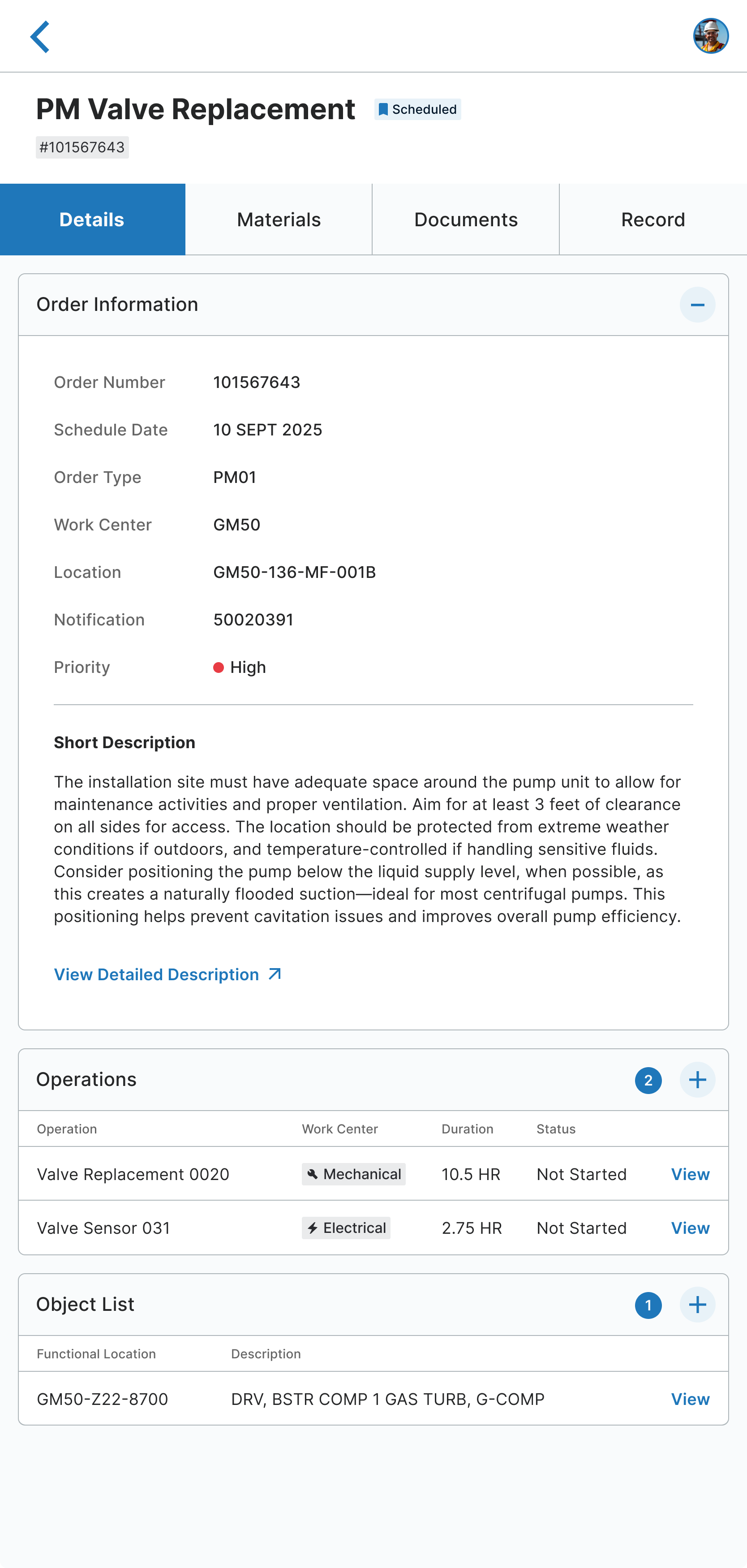

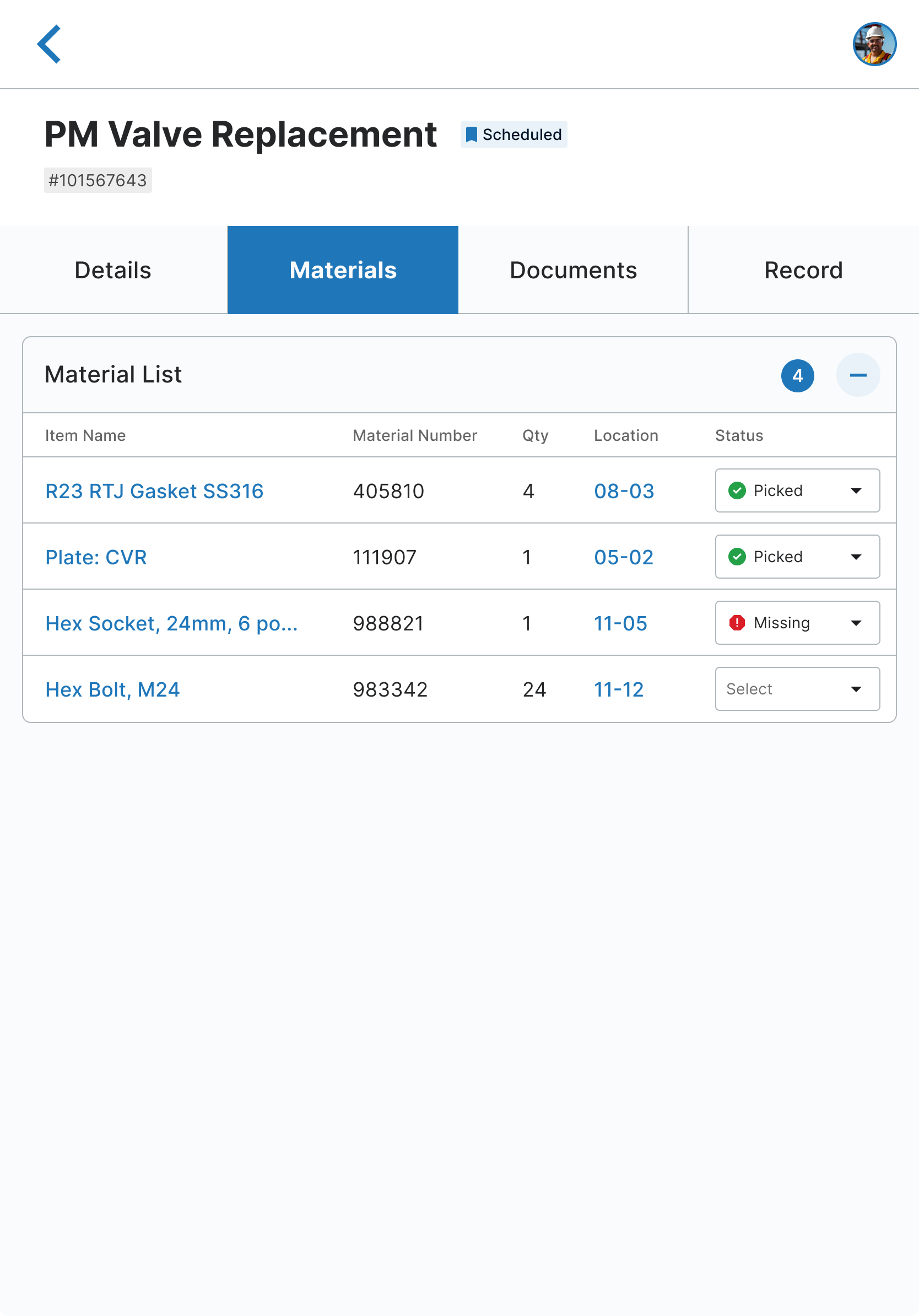

Each technician will only view work assigned to them. When a specific order is selected, the technician will have access to all the necessary information related to that order – which is broken down into tabs: Details, Materials, Documents, and Complete Work.

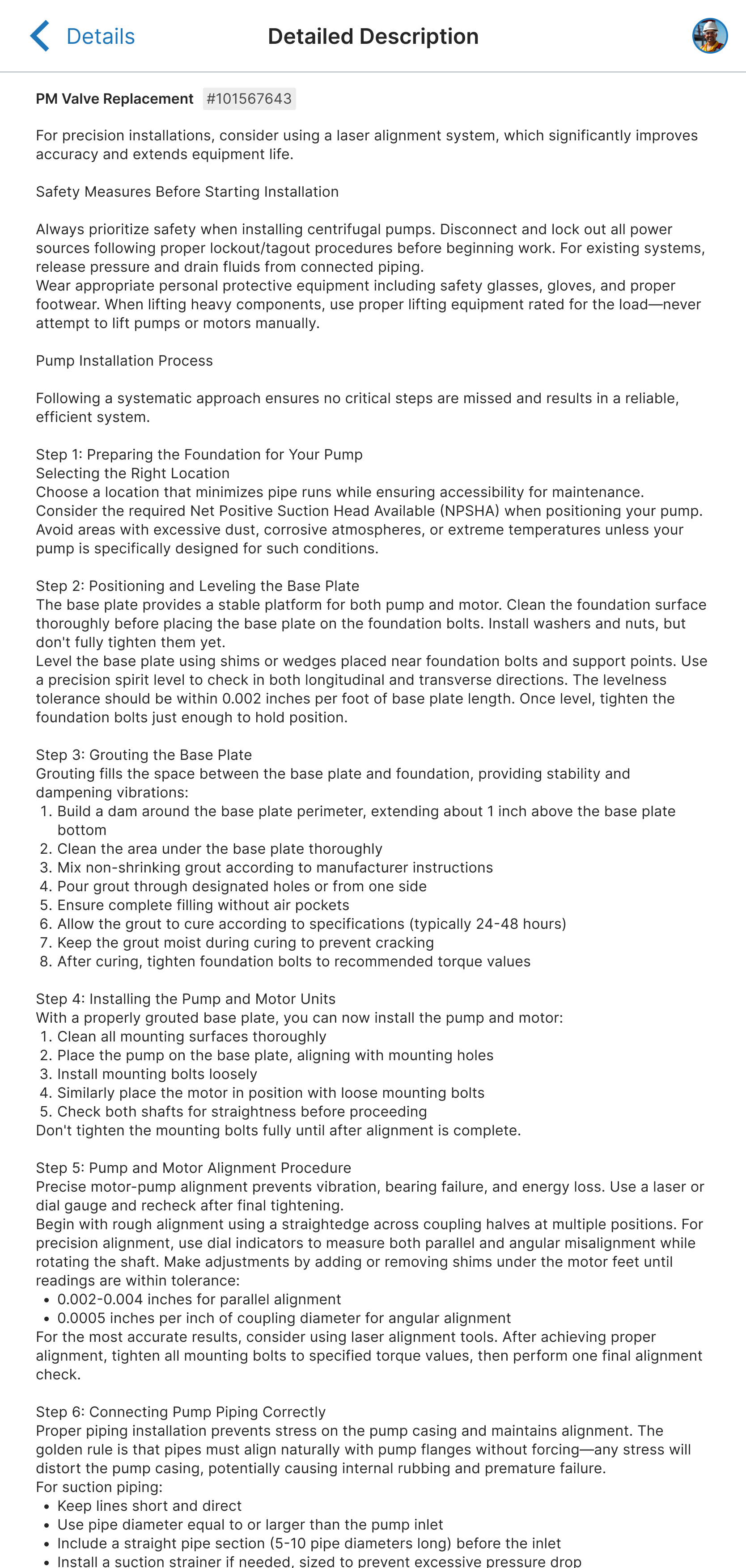

01 Details section of the Maintenance Order 02 Details section of Maintenance Order with all information sections expanded 03 The Detailed Description page, often includes directions, details, and notes about the order, found under ‘Order Information’

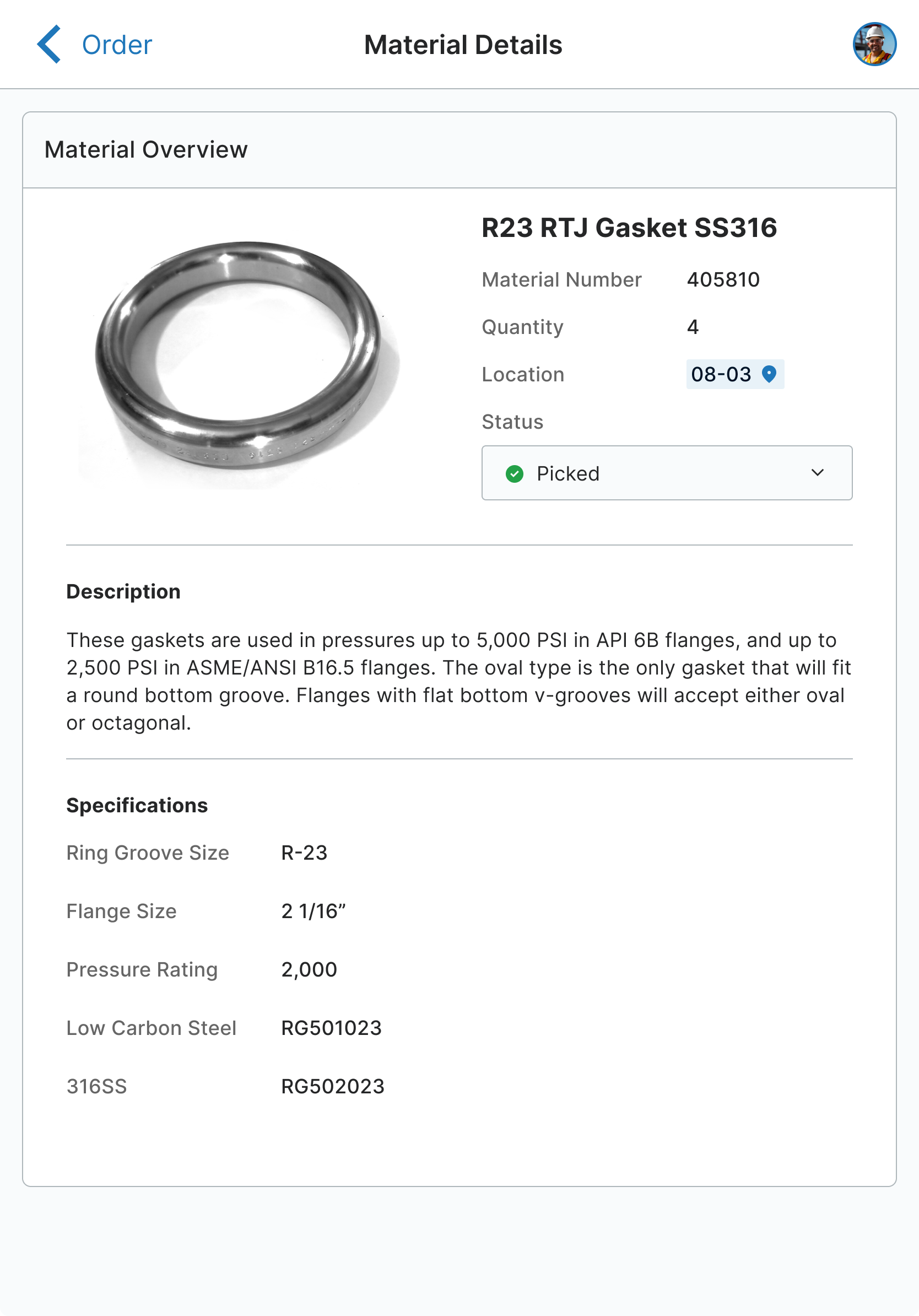

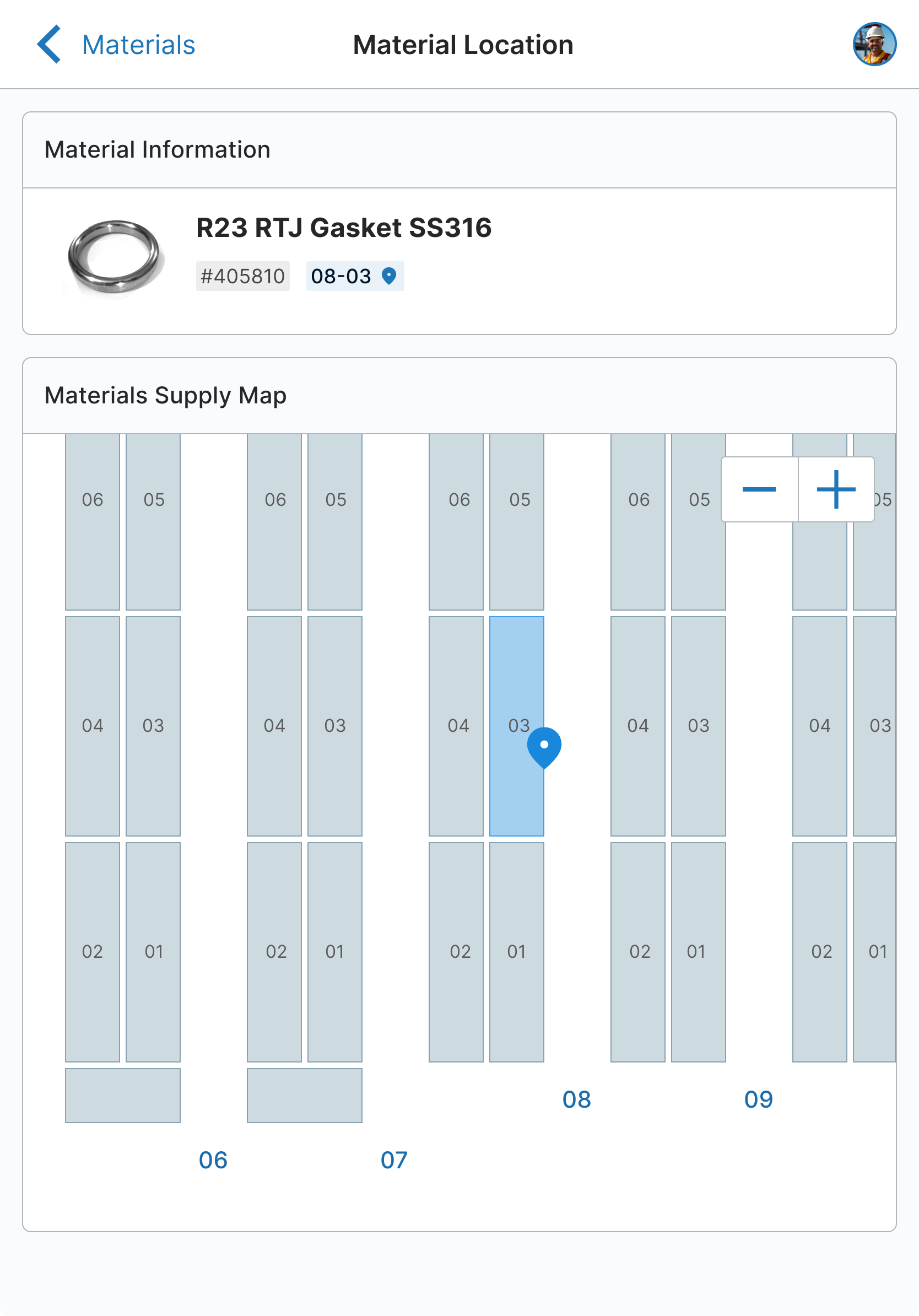

A recurring pain point involved the locating and procurement of materials needed to complete work orders. Technicians would often waste time searching for materials, or finding a material’s storage location only to discover it was missing. The new Materials feature displays a map of inventory storage, the ability to view material details, and to mark each item as collected or missing.

MATERIALS

01 Materials section of the Maintenance Order - where user reviews all materials (tools, parts, etc.) needed for order 02 Material Detail Page to view material specs 03 Map view of location of material in storage

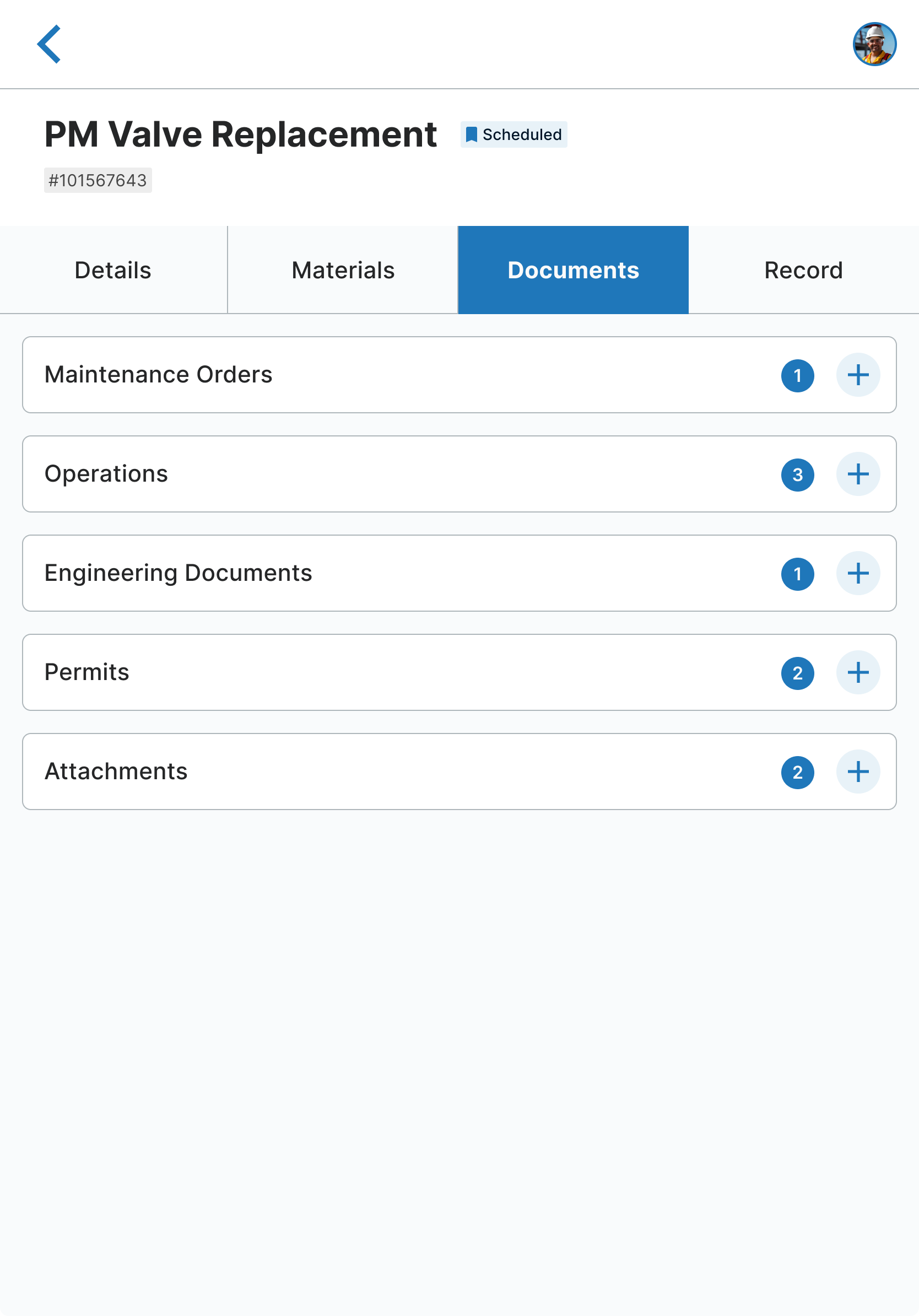

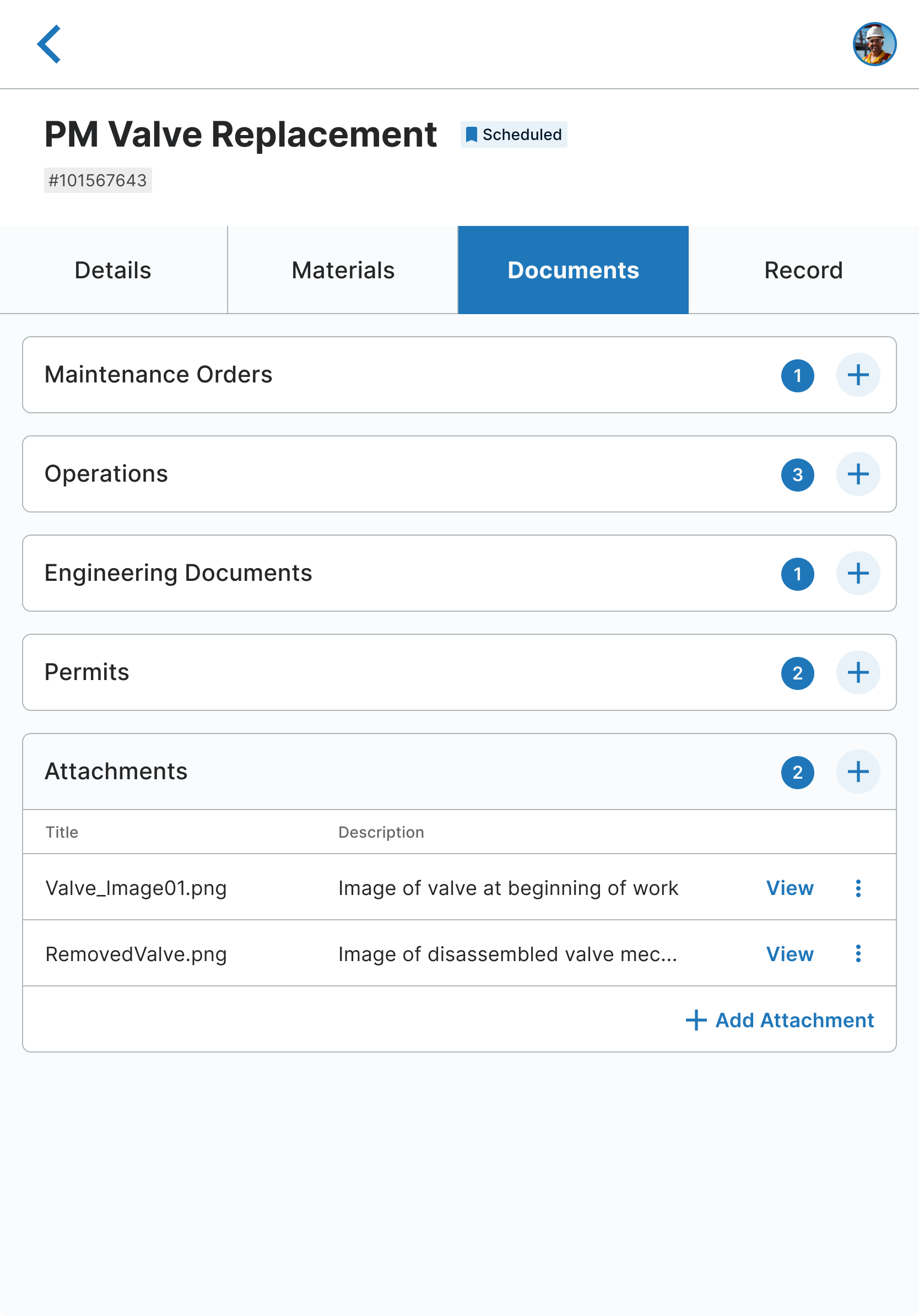

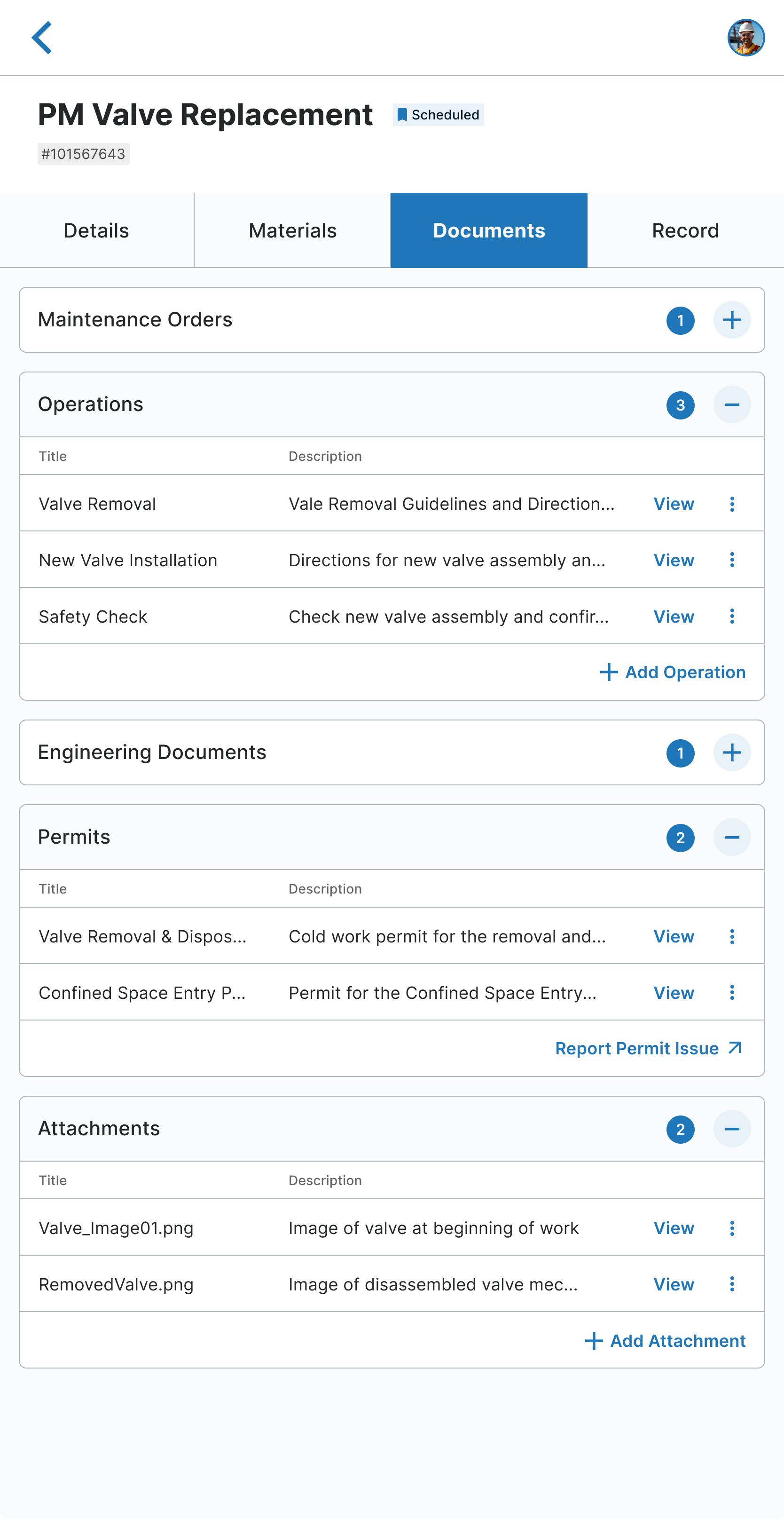

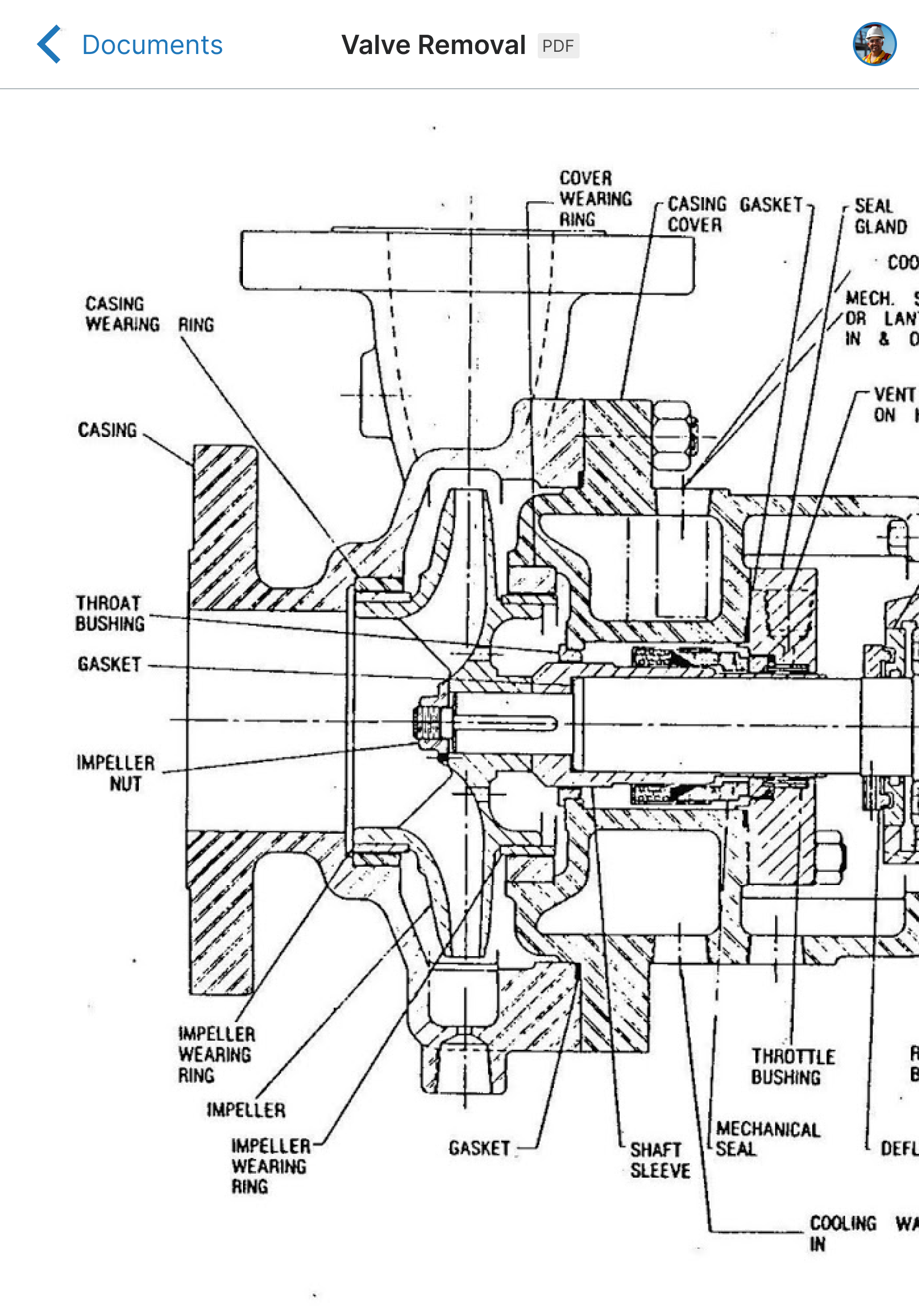

Nearly every maintenance project completed has substantial documentation attached, including but not limited to mechanical and structural documentation, maintenance instructions, and importantly, permits. The documents section organizes and displays these items as needed.

DOCUMENTS

01 Document section of the Maintenance Order - where users can access all documents needed for the order (incl. permits, engineering files, instructions, etc.) 02 Document section with Attachments expanded

01 Document section of the Maintenance Order - viewing more items expanded 02 Example of a document being viewed

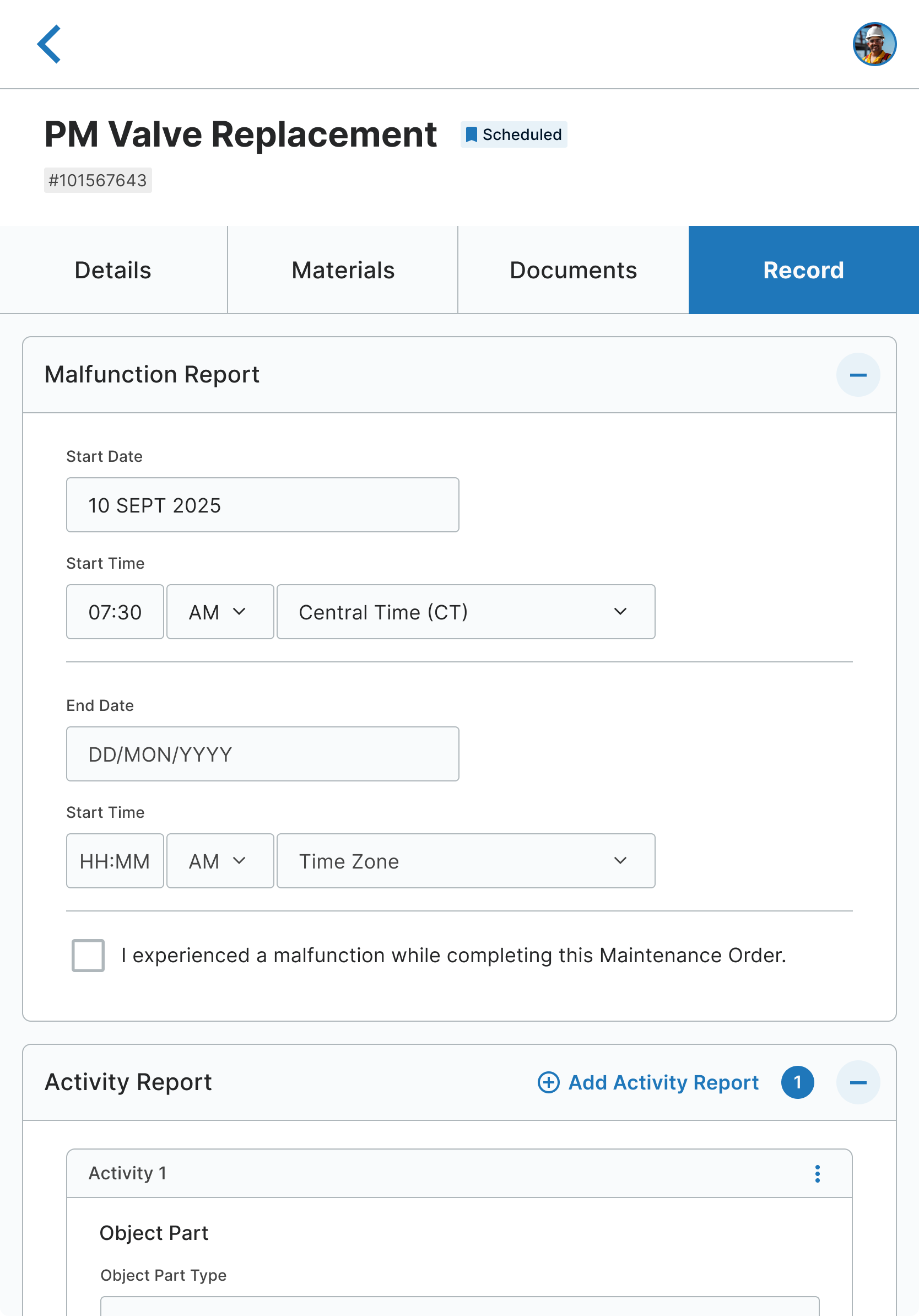

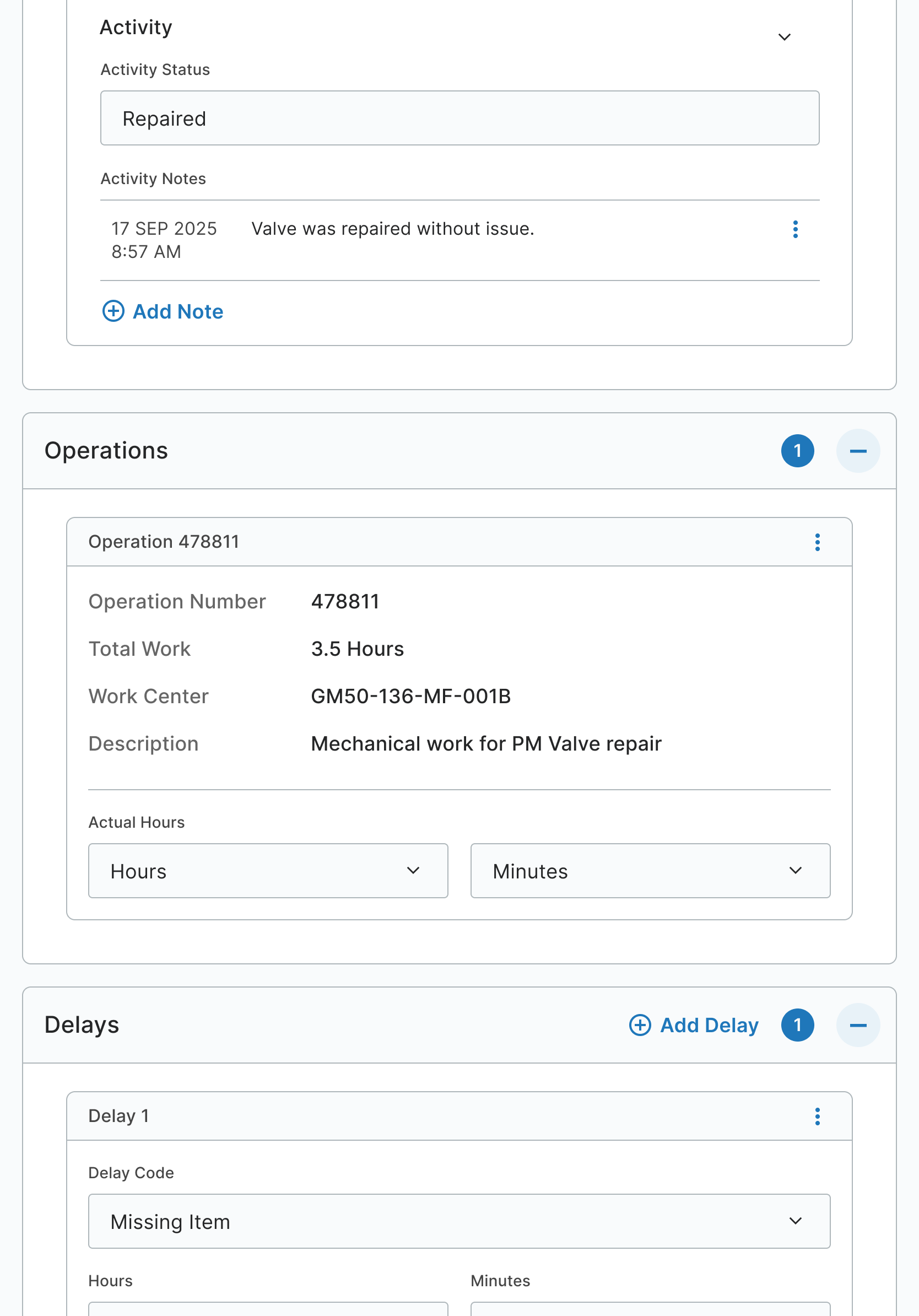

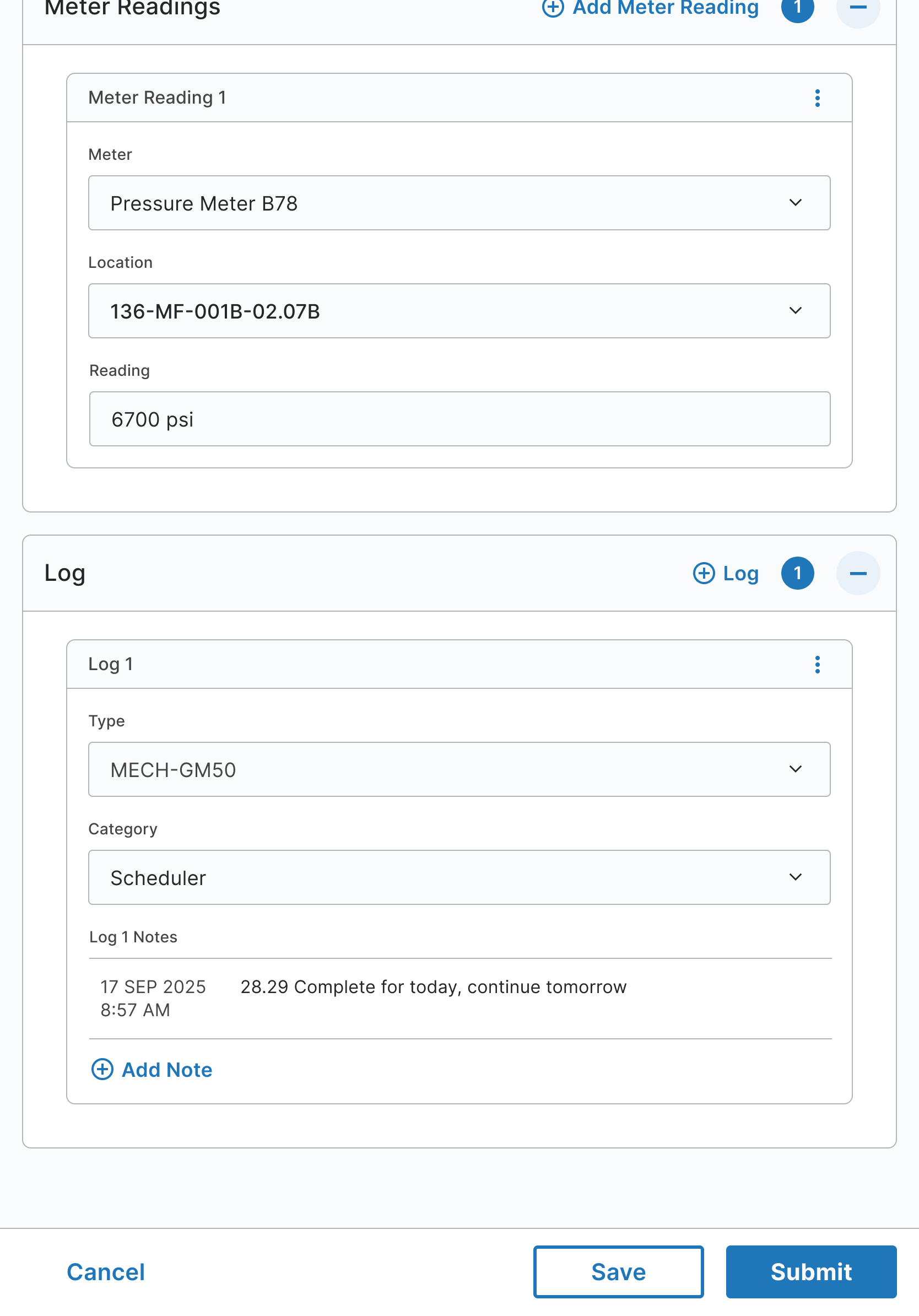

Technicians will complete their work by entering data and notes in the final section: Record. There they’ll enter malfunction details, delays, tasks performed, meter readings, and lastly, if the work is completed.

RECORD / COMPLETE WORK

01-03 The Record section of the Maintenance Order - this is where users will record details about the entire maintenance order - things like delays, meter readings, time of task completion, and more

OUTCOME

Bringing Maintenance into the Digital Era

With the hard work and contributions from the users, client, our research team, and design – the client built an MVP to be used in-field with technicians. The initial MVP experience was tested with a maintenance team based in the Gulf of Mexico.